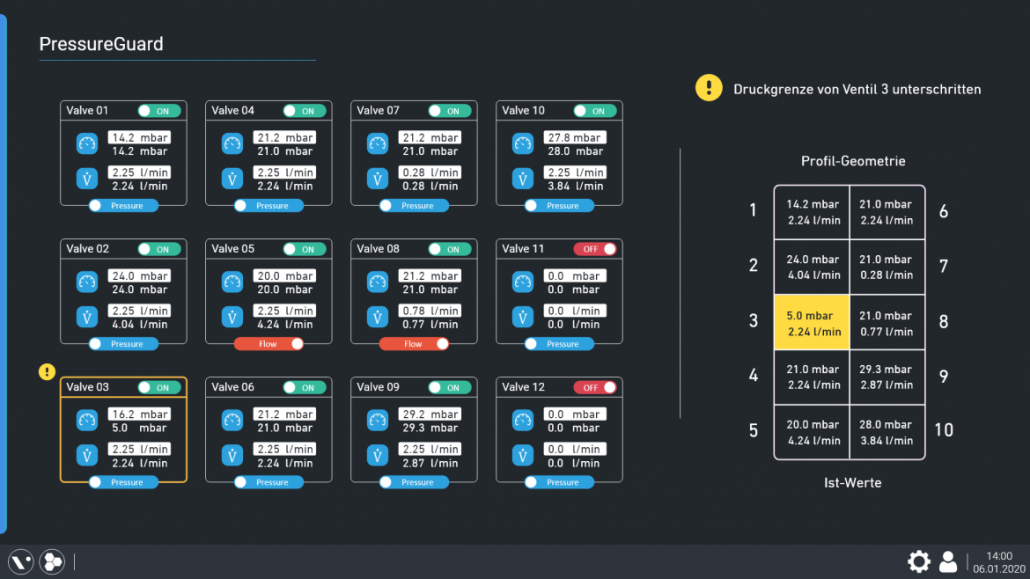

pressureGUARD

The pressureGUARD allows the exact regulation of the pressure or the volume flow in each individual hollow chamber of a hollow chamber profile covered with supporting air. Thus, processes can be started up quickly and robustly and stable and high quality production can be achieved over long periods of time. The pressureGUARD is therefore an indispensable aid for the extrusion of high-quality hollow chamber profiles.