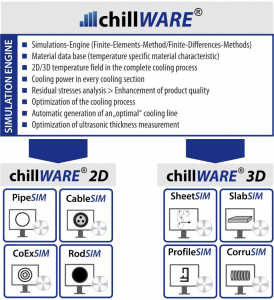

chillWARE® – cooling simulation for plastics processing

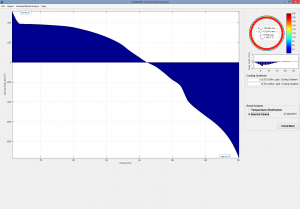

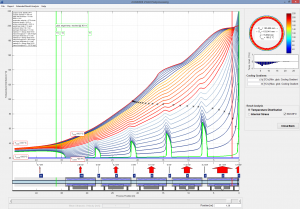

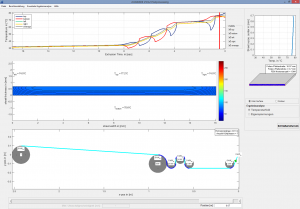

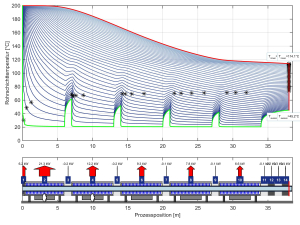

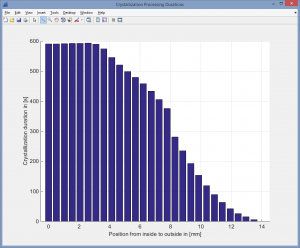

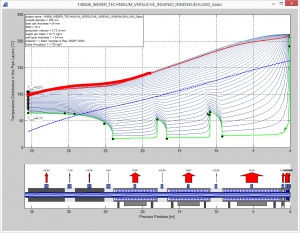

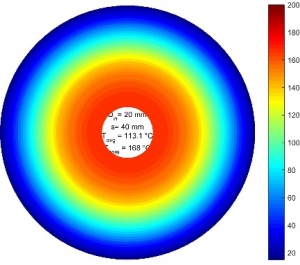

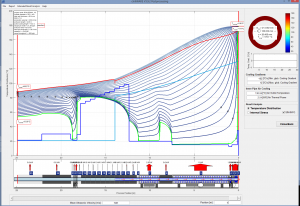

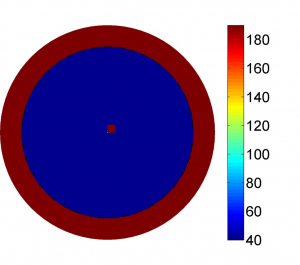

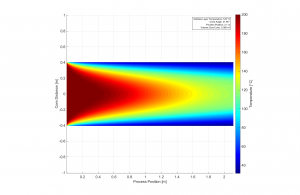

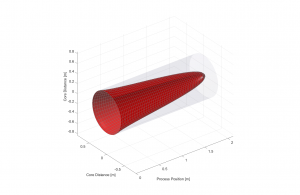

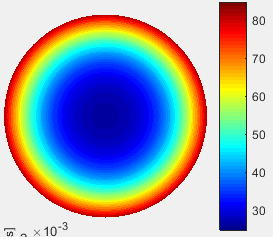

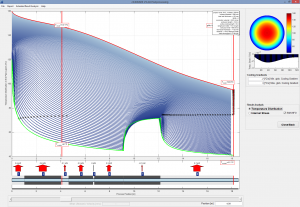

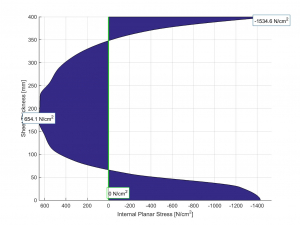

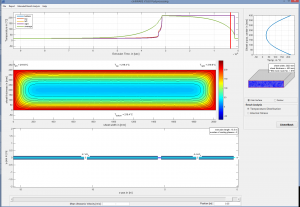

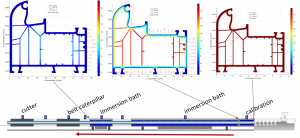

The chillWARE® cooling simulation offers the exact thermodynamic simulation of cooling processes during the processing of plastics.

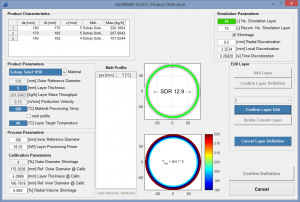

The simulation is especially designed for the needs of plastics processing and only the input data is needed, which can be read directly at the extrusion line.

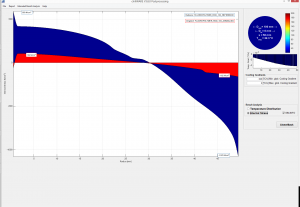

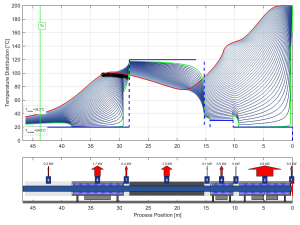

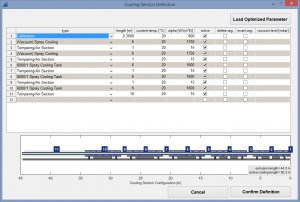

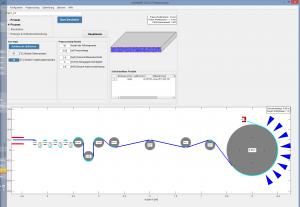

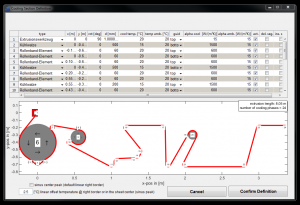

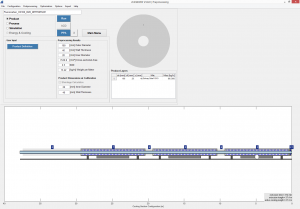

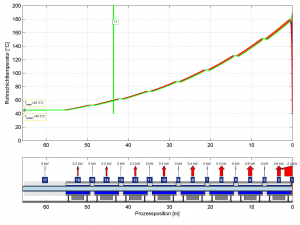

The simulation modules offer in one input mask the possibility to transfer relevant process parameters directly into the system. Only the data of the product dimension and the cooling line design, the mass throughput or the haul-off speed as well as the data of the temperatures in the different segments of the cooling line are needed.

Depending on the application and complexity, the calculation time of the simulation is usually in the range of a few seconds up to minutes.

The chillWARE system has been awarded second place in the category “Product of the Year” by the plastics processor several times in a row.