Consulting

SHS supports you in solving your production problems or helps you to increase your productivity or product quality. Our experts act like your (external) employees. Both as project cooperation, with a concrete and clearly defined topic and time requirement, and in the partner program as a constant (external) department.

Simulation

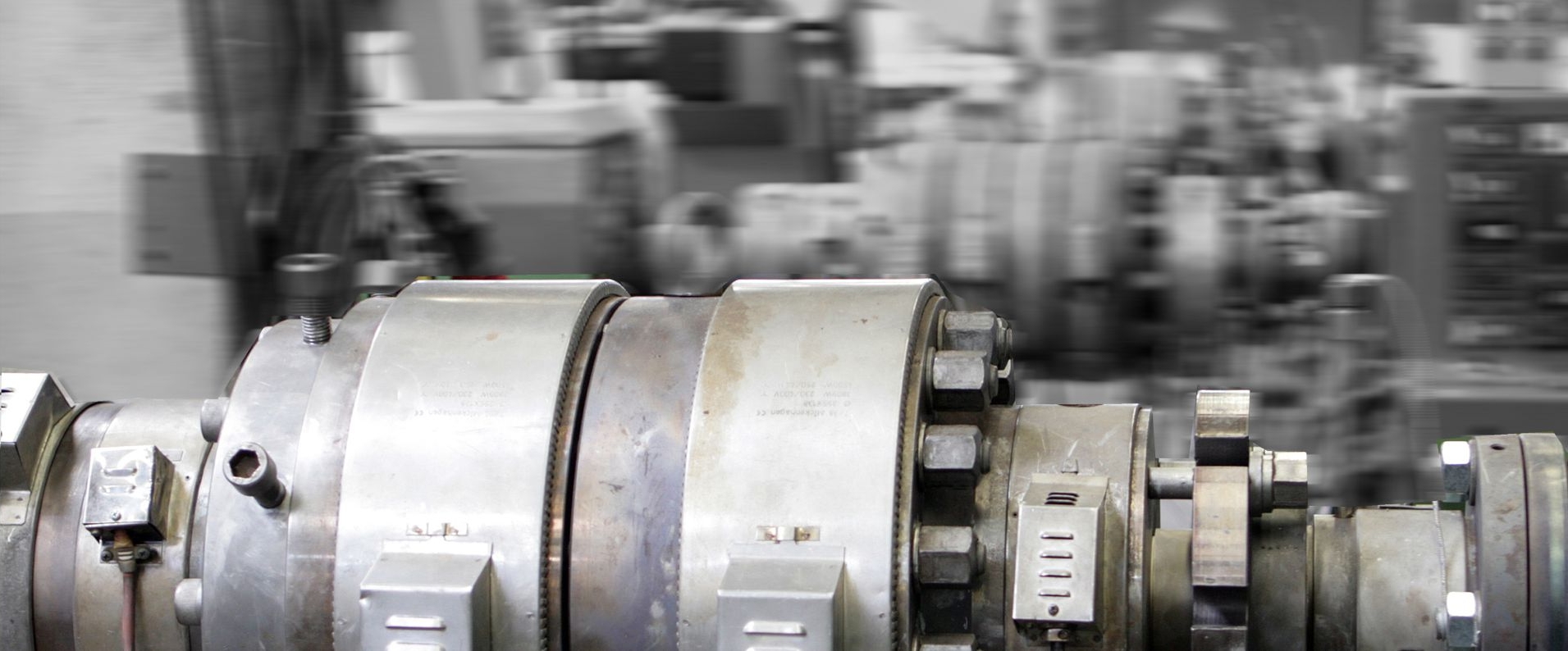

SHS calculates your plastics processing with state-of-the-art computer simulation capabilities. Whether single-screw extruder, extrusion die, cooling section or tempering processes, with our simulation systems we have a great deal of experience in almost every field of application in plastics processing.

Automation

SHS develops series (PLC) control systems as an OEM supplier for well-known, internationally operating machine and plant manufacturers and offers customized control solutions for any plastics processing plant. Whether extruder, winder, smoothing unit or a complete blow moulding line, we develop your modern industry 4.0 control system.

Virtuelle Assistenz

In the combination of our business areas “automation” and “software development” paired with our wealth of experience in “problem solutions in plastics processing”, SHS develops “virtual assistance systems” that support the plant operator in driving robust and high-quality processes. We do not only rely on modern methods from the field of artificial intelligence, but also combine these approaches with classical expert knowledge and a wealth of experience.